|

PFR-3 (Electric)

PFR-3-A/P (Air Powered)

SUPER-PFR-3-A/P (Air Powered)

- Powerful electric flux recovery system.

- Revolutionary (patented) self-cleaning dust and fines filter.

- Dust and fines collected in dust bag for easy dumping.

- Fused slag is automatically separated from flux.

- Flashing light tells operator when to clean dust bag.

- Pressure flux tank feeds flux to remote welding gun.

- Adjustable and locking pressure flow regulator.

- Flux is tranferred from upper recovery chamber to lower pressure tank by turning a simple hand-wheel valve.

- Portable and easily moved.

- Option: MAGSEP-2 magnetic separator.

- Converts most wire feeders into a submerged arc welding system.

- Comes complete with 15 ft. of vacuum hose (10 ft. of vacuum hose with PFR-3-A/P) and 20 ft. of flux feeding hose.

- Designed for standard duty welding applications. See PFR-3000 series for heavy duty applications.

- Manufactured with an internal flux cone. This allows complete draining of all flux out of tank. There is no stagnant area in the tank from which flux will not flow out of tank.

Tank Options

Open Literature Page (PDF)

|

LPFR-3 (Electric)

LPFR-3-A/P (Air Powered)

SUPER-LPFR-3-A/P (Air Powered)

- For direct mounting on most manufacturer’s pressurized flux feed tank.

- Screws on top of tank in place of pressure cap in minutes!

- Powerful electric flux recovery system.

- Revolutionary (patented) self-cleaning dust and fines filter.

- Dust and fines collected in dust bag for easy dumping.

- Fused slag is automatically separated from flux.

- Flashing light tells operator when to clean dust bag.

- Flux is tranferred from upper recovery chamber to lower pressure tank by turning a simple hand-wheel valve.

- Option: MAGSEP-2 magnetic separator.

- Comes complete with 15 ft. of vacuum hose (10 ft. of vacuum hose with LPFR-3-A/P), nozzle and remote on/off pendent at nozzle end of hose.

- Designed for standard duty welding applications. See LPFR-3000 series for heavy duty applications.

- Manufactured with an internal flux cone. This allows complete draining of all flux out of tank. There is no stagnant area in the tank from which flux will not flow out of tank.

Tank Options

Open Literature Page (PDF)

|

PT-100 (Left)

HPT-100 (Right)

HPT-100/D

- The PT-“x”00 is a flux pressure feed tank system for pressure feeding flux to a flux hopper or weldinf torch.

- Many tank sizes available:

- PT-3 (60 lbs. of flux)

- PT-100 & HPT-100 (100 lbs. of flux)

- PT-300 & HPT-300 (300 lbs. of flux)

- PT-600 & HPT-600 (600 lbs. of flux)

- PT-1200 & HPT-1200 (1200 lbs. of flux)

- PT-2000 & HPT-2000 (2000 lbs. of flux)

- Other tank sizes available.

- Electronic low or high flux level sensor is an option available for all size pressure tanks.

- HPT-“x”00 Heated Flux Pressure Feed Tank. Same as above but is heated to 250°F (121°C), adjustable.

- HPT-“x”00/D Heated Flux Pressure Feed Tank with Built-In Dryer Unit. Incoming shop air first passes through an oil and water trap, then a micron filter, and then through a refrigerated air dryer, before finally pressurizing the flux tank with very clean dry air.

- All pressure tanks manufactured with an internal flux cone. This allows complete draining of all flux out of tank. There is no stagnant area in the tank from which flux will not flow out of tank.

Tank Options

Complete System Diagrams

Open Literature Page (PDF)

|

|

LPFR-3000 (shown)

HLPFR-3000 (heated)

- The LPFR-3000 flux recovery system (less the tank) mounts directly to the pressurized flux feed tank.

- Screws on the tank in place of the pressure cap.

- Recovers all unfused flux and transfers flux to presure tank via a butterfly valve and geared hand-wheel opener.

- Standard LPFR-3000 has approximately a 150 lb capacity. Other sizes available.

- Requires a “Mighty-Mac” vacuum to provide vacuum power.

- Option: MAGSEP-100 magnetic separator.

- HLPFR-3000 is the same as the LPFR-3000 except it is heated under continuous control upto 250°F (122°C).

- Manufactured with an internal flux cone. This allows complete draining of all flux out of tank. There is no stagnant area in the tank from which flux will not flow out of tank.

Tank Options

Complete System Diagrams

Open Literature Page (PDF)

|

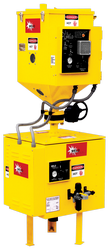

PFR-3000 (left)

HPFR-3000 (heated) (right)

- Recovers flux back to flux separation hopper; recovered flux is then pressure-fed to torch or welding equipment hopper.

- Requires a “Mighty-Mac” vacuum to provide vacuum power.

- Many hopper and tank sizes available for the PFR-3000 and HPFR-3000 series:

- PFR-3000 Standard

(150 lb. Hopper, 100 lb. Tank)

- PFR-3000-300-300

(300 lb. Hopper, 300 lb. Tank)

- PFR-3000-400-600

(400 lb. Hopper, 600 lb. Tank)

- PFR-3000-1000-1200

(1000 lb. Hopper, 1200 lb. Tank)

- PFR-3000-1500-2000 & HPT-2000

(1500 lb. Hopper, 2000 lb. Tank)

- Other sizes available for hopper and tank.

- Option: MAGSEP-100 magnetic separator.

- Option: Electronic Flux Level Sensor. A high or low flux level sensor is available to sense flux level of pressure tank or hopper. A loud audible alarm and flashing red light on control panel will signal operator.

- HPFR-3000 is the same as the PFR-3000 except it is heated under continuous control upto 250°F (122°C). Either or both the hopper and tank may be heated.

- Manufactured with an internal flux cone. This allows complete draining of all flux out of tank. There is no stagnant area in the tank from which flux will not flow out of tank.

Tank Options

Complete System Diagrams

Open Literature Page (PDF)

|

FTV-3000

- Automatic transfer valve for PFR-3000, HPFR-3000 existing and new.

- Automatically transfers flux from the upper hopper to the lower pressure tank with a push of a button on the control or remote pendant.

- Easy to install in the field on existing or factory installed on new PFR-3000 and HPFR-3000.

Open Literature Page (PDF)

|