|

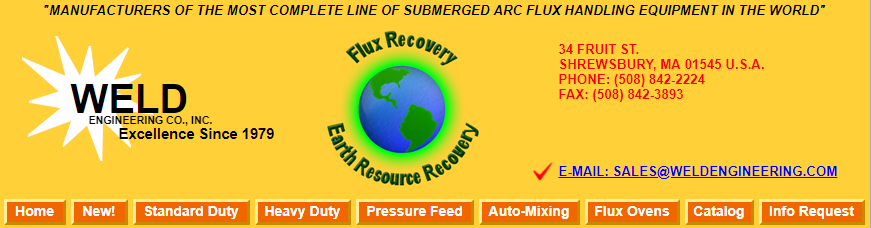

Mighty Might AS-4

& AS-4-E/P (auto transfer)

(shown mounted on an automatic welding head)

- Revolutionary (patented) self-cleaning dust and fines filter enables hours of uninterrupted operations.

- Flashing light tells operator when to clean dust bag for maximum efficiency.

- Remote control on/off pendent. Turn AS-4 on and off with weld cycle.

- Direct recycling of flux back to hopper.

- Fused slag is automatically separated from flux.

- Dust and fines are collected in a dust bag for easy dumping.

- Sight window in AS-4 and hopper for easy flux level indication.

- Versatile, with quick attach options.

- AS-4-E/P Automatic flux transfer Mighty-Might electric flux vacuum.

Open Literature Page (PDF)

Complete System Diagrams:

AS-4 Drawing (IMAGE)

AS-4-E/P Drawing (IMAGE)

AS-4 W/ PAS-1 Drawing (IMAGE)

View Optional Accessories

|

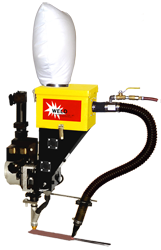

Mighty Might AP-1,

Mighty Might SUPER-AP-1,

AP-1-E/P (auto transfer)

- AIR POWERED

- Inexpensive, rugged, and powerful; the AP-1 mounts easily onto most automatic submerged arc welding equipment.

- Adds no oil or water to the flux and produces no damage to the recovered flux particles, since flux is never in compressed air stream.

- Vacuum air pump is on exhaust side and undesirable contaminants, fines and dust are discharged into a very efficient dust bag assembly.

- No Moving parts in air pump, and no internal filters to wear out.

- Very efficient pump produces a higher vacuum, uses less air, and is quieter than most competitive models.

- AP-1-E/P and Super AP-1-E/P Automatic transfer of flux to lower hopper without operator input.

- Super-AP-1 has twice the vacuum power and twice the flux capacity than the AP-1.

AP-1 Literature (PDF)

SUPER AP-1 Literature (PDF)

View Complete System Drawings:

AP-1 Drawing (IMAGE)

AP-1-E/P Drawing (IMAGE)

SUPER AP-1 Drawing (IMAGE)

SUPER AP-1-E/P Drawing (IMAGE)

AP-1 W/ PAS-1 Drawing (IMAGE)

View Optional Accessories

|

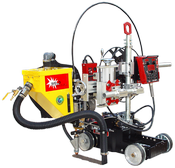

Ultra Compact XP-3

(shown mounted on Lincoln Electric welding equipment with optional PT-100 feed tank)

- AIR POWERED

- Inexpensive, lightweight, very compact, rugged, and powerful; the XP-3 mounts easily onto most automatic submerged arc welding equipment.

- Continuously feeds recovered flux to weld nozzle without need of any transfer valve.

- Slag, dust, and fines are automatically removed from recovered flux.

- No moving parts in air pump.

- Small size makes XP-3 ideal for internal vessel welding and flux recovery.

- Optional PT-100 or Heated HPT-100 100Lb. (45Kg) pressure feed tank and optional FF-3 flux feed pipe enables a continuous flux supply equal to size of feed tank [also available is the 300Lb. (136Kg) (PT-300 or Heated HPT-300), 600Lb. (272Kg) (PT-600 or Heated HPT-600), or larger pressure feed tanks.]

Open Literature Page (PDF)

Complete System Drawings:

XP-3 Drawing (IMAGE)

View Optional Accessories

|

Low Maintenance

XP-4T

- AIR POWERED

- Lightweight and compact.

- Recycles flux dust. Does not require any emptying of the dust bag.

- Vertical dust bag allows flux dust to be recycled back into the system.

- Continuously feeds recovered flux to weld nozzle without need of any transfer valve.

- Slag is automatically removed from recovered flux.

- No moving parts in the air pump. Very efficient air pump produces higher vacuum and uses less air and is much quieter than most competitive models.

- Optional PT-100 or Heated HPT-100 100Lb. (45Kg) pressure feed tank and optional FF-3 flux feed pipe enables a continuous flux supply equal to size of feed tank [also available is the 300Lb. (136Kg) (PT-300 or Heated HPT-300), 600Lb. (272Kg) (PT-600 or Heated HPT-600), or larger pressure feed tanks.]

Open Literature Page (PDF)

Complete System Diagrams:

XP-4T Drawing (IMAGE)

View Optional Accessories

|

|

Mighty-Might PS-2

(electric, shown)

and PS-2-A/P

(air powered)

- Powerful electric or air vacuum can meet your medium duty flux recovery.

- Revolutionary (patented) self cleaning dust filter in PS-2 and no internal filters inPS-2-A/P enables hours of uninterupted operation.

- Flashing light tells operator when to clean dust bag (PS-2 only).

- Remote on/off control switch is attached to hose near nozzle, enabling operator to turn PS-2 on and off as needed. (PS-2 only).

- Dust and fines are collected in a dust bag for easy cleaning.

- Fused slag is automatically separated from reusable flux by internal slag tray.

- Holds approximately 75 lbs. (34 kgs.) of recovered flux.

- Flux slide valve on bottom of hopper enables easy transfer of recovered flux.

Open Literature Page (PDF)

View Optional Accessories

|

Super-FH-100-A/P (unheated)

Super-HFH-100-A/P (heated) (shown)

- AIR POWERED

- Powerful air vacuum (equivalent to many 3 H.P. electric vacuums)

- Adds no oil or water to the flux and produces no damage to the recovered flux particles, since flux is never in compressed air stream.

- Vacuum air pump is on exhaust side and undesirable contaminants, fines and dust are discharged into a very efficient dust bag assembly.

- No Moving parts in air pump, and no internal filters to wear out.

- Very efficient pump produces a higher vacuum, uses less air, and is quieter than most competitive models.

- 150 lb. flux capacity enables long weld periods without the addition of new flux.

- Recovered flux gravity feeds continuously back to the welding head flux hopper or torch with no transfer valves involved.

- Optional Super-FH-100-A/P-E/P does not require a specific “Head Height” above the welding torch or hopper as Super-FH-100-A/P does)

- Heated Super-HFH-100-A/P has heat elements that run throughout the flux for uniform heating to 250 F(121 C). It also has temperature control and an accurate thermometer.

Open Literature Page (PDF)

Complete System Diagrams:

SUPER-FH-100-A/P & SUPER-FH-100-A/P-E/P Drawing (IMAGE)

View Optional Accessories

|

DC-30

Dust Collector

- Vacuum sensing gauge indicates when filter needs to be cleaned.

- Dirty filter is semi-automatically cleaned by high energy shock wave of air.

- Dust is automatically collected in dust drawer for easy removal.

- “Micron” cartridge dust filter is long lasting and easily replaced.

- Dust drawer holds many times more dust than a standard dust bag.

- Filter lasts much longer than a standard dust bag.

Open Literature Page (PDF)

View Other Accessories

|

|

|

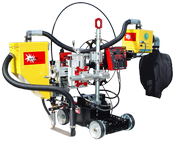

Mighty-Might

APT-2-C

& APT-2

- Adds no oil or water to the flux and produces no damage to the recovered flux particles, since flux is never in compressed air stream.

- Vacuum air pump is on exhaust side and undesirable contaminants, fines and dust are discharged into a very efficient dust bag assembly.

- No moving parts in air pump, and no internal filters to wear out.

- Very efficient air pump produces a higher vacuum, uses less air, and is quieter than most competitive models.

- Ultra-lightweight aluminum construction.

- New flux is easliy added to APT-2 hopper through spout without interrupting weld, enabling indefinite weld length.

APT-2 “LT-7” Literature (PDF)

NEW! “Cruiser” Literature (PDF)

View Optional Accessories

|

Ultra Lightweight

XP-3TRAC-C

& XP-3TRAC

- Lightweight, very compact, rugged, and powerful; the XP-3TRAC mounts easily onto most automatic submerged arc welding tractors. Also ideal for other applications where size and weight are important factors.

- Continuously feeds recovered flux to welding nozzle without need of any transfer valve.

- Slag, dust and fines are automatically removed from recovered flux.

- No moving parts in air pump. Very high efficient air pump produces higher vacuum. Uses less air and is quieter than most competitive models.

- XP-3TRAC-OTC for OTC tractor mounting.

XP-3TRAC “LT-7” Literature (PDF)

NEW! “Cruiser” Literature (PDF)

View Optional Accessories

|

Mighty-Might

ALT-2-C

& ALT-2

- Mounts directly to most submerged arc welding tractors.

- Ultra-lightweight aluminum construction.

- Modular two piece design enables perfect balance and minimizes weight on flux hopper.

- Powerful electric vacuum can meet your high flux recovery demand.

- Revolutionary (patented) self-cleaning dust and fines filter enables hours of uninterrupted operation.

- Flashing light tells operator when to clean dust bag for maximum efficiency.

- Direct recycling of flux back to hopper.

- Fused slag is automatically separated from flux.

- New flux can be easily added without interrupting the weld, enabling indefinite weld length.

ALT-2 “LT-7” Literature (PDF)

NEW! “Cruiser” Literature (PDF)

View Optional Accessories

|

|